NoPak Boosters and Valves

Boosters

Boosters are designed to convert low pressure shop air into an intensified hydraulic pressure. This is to eliminate costly hydraulic pumps or power back units.

Cylinder Tubing: Hard coated aluminum, incorporating an extremely wear resistant surface, and low friction hydraulic cylinders.

Tube Seal: Positive Controlled Metal Squeeze on Pressure Sealed O-Ring

Rod Seals: Are self comensating to pressure, multilip vee type packing. Specifically designed for high pressure sealing and minimum leakage.

Rod Bearing: Long wearing type bronze is concentrically machined for accurate alignment insuring longer seal life.

Ports: are machined as a SAE dry seal national pipe thread standard

Tie Rods and Locknuts: Tie rod material is an alloy steel for maximum strength. Nuts are of high strength steel material and designed for self locking.

Piston Assembly: a one piece piston, machined from high strength cast iron. Two u-cup seals are of the pressure comensating sealing type backed up by teflon non-extreusion washers.

Piston Rod: hard chrome plated stressproof steel, ground and polished, 125,000 tensile Rockwell 25C

End Caps and Ram Nozzle: accurately machined from high quality steel plate or bar stock.

Hand and Foot Valves

Nopak Hand and Foot Controlled Valves have a patented rotating lapped disc. This simple design is long lasting, with little to no maintenance.

Precision Control: Positive precision control through the complete cycle of valve operation, from slow gradual throttling action of instant full opening, without damaging shock, impact, or pressure cutting.

Sealing Surfaces: The precision-lapped seaing surfaces actually improve with use due to the “lapping-in” process continuing while the valve is operated.

Protection Against Grit, Abrasion, or Wire Drawing: The valve is always covered by the rotating disc so both sealing surfaces are always shielded from direct pressure flow and possible abrasion. An internal channel carries off any abrasive materials without damage.

Pressure Sealing: Line pressure is exerted against the valve disc at all times to keep the lapped surfaces positively sealed.

Packless Construction: Valves depend entirely upon metal-to-metal, precision lapped sealing surfaces for their leak-proof construction. When used for hydraulic service additional protection against leakage past the valve stem has been provided by the use of an “O” Ring in the valve body and around the stem, just below the operating handle.

Single Solenoid Valve

Nopak Matic Solenoid Valves are designed as compact, rugged and economically priced to solve the most demanding solenoid pilot operated air valve applications.

Developed especially as a compact, rugged, exonomically priced valve to solve the most demanidng solenoid pilot operated air valve applications.

Simple pilot head operator is tolerant to dry, unlubricated air and dusty atmospheric conditions. Ideal for heavy duty batching plant, construction, excavation, and foundry applications.

It’s fast action produces instantaneous valve response, even after long periods of solenoid energization or de-energization.

One pilot head fits all pipe size standard Nopak-Matic master valves.

Efficient solenoid pilot rated at 10 operating watts in closed position

Explosion proof

Complete valve assembly can be replaced in less than 2 minutes; without disturbing piping.

The replaceable, self-cleaning seats are fast and inexpensive to replace. Only 2 seat sizes are required to fit all valves and are completely interchangeable.

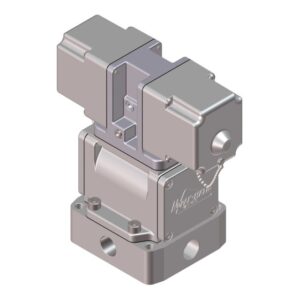

Double Solenoid Valve

Nopak Matic Solenoid Valves are designed to be compact, rugged and economically priced to solve the most demanding solenoid pilot operated air valve applications.

“Flow Director” Pilot Head: simplifies piping and makes desired valve operation simply by piping to the proper port.

Interchangeable Pilot Heads: any pilot head fits any valve, regardless of type or size

Solenoids: Low amperage, cotinuously rated industrial-type with hardened plunger faces.

Replaceable, Self-Cleaning Seats: fast and inexpensive replacement of all seats. Poppets do not seat on valve body.

Positive Sealing: resilient, bonded poppet seals ensure leak-proof operation and long life.

Rapid Response: valve shifts in less than 0.05 of a second.

Full Flow: All passages over-sized for minimum pressure drop through the valve (up to 1″)

No Springs: Piston-poppets shift with air pressure

Light Weight, Compact Design: Aluminum used extensively and smaller overall dimensions. Every model has a clean, neat appearance that compliments modern machine design.

Corrosion Resistant: All materials are corrosion resistant

Parts Interchangeability: Design allows maximum parts interchangeability from one valve to another; and perfect “non-selected” fit of factory shipped maintenance parts.

Simplified Piping: exclusive “Flow-Director” allows piping with fewer fittings and makes fewer valves adaptable to more applications.

We offer the above from the following Brands