American Cylinders Pneumatic Non-Repairable Cylinders

NON-REPAIRABLE PNEUMATIC CYLINDERS

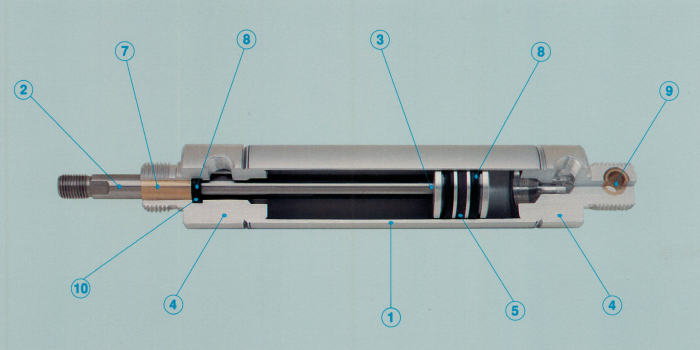

Stainless Steel Pneumatic Cylinders

Stainless Steel Body Air Cylinders Available in a Variety of Interchangeable Mounting Styles Ranging from 5/16″ thru 3″ Bore. Stainless Steel Rods are Standard.

Stainless Steel Cylinder Body: Type 304 Stainless Steel manufactured to special mill specifications and tolerances to insure a long cylinder life.

Stainless Steel Rod: Ground & Polished Type 303 Stainless Steel rods are standard on the Stainless Steel Series. All rods 1/4″ diameter and larger have wrench flats and stress relief grooves.

Piston Rod Assembly: Piston rods are threaded, anaerobically sealed, and machine staked into the piston for triple protection.

End Caps, Piston: High strength aluminum alloy.

Magnet for Sensing Switch Actuation: Optional, refer to American Cylinder’s MFC® catalog for details.

Springs: Springs for spring action cylinders are made from music wire and designed for millions of cycles. Special spring forces are available.

Rod Guide Bushing: Standard on all models. The oil impregnated sintered bronze bushing increases the life of the cylinder rod and provides a non-abrasive bearing surface.

Buna-N U-Cup Rod & Piston Seals: U-Cup seals provide low breakaway friction and maximize cylinder life expectancy. Standard Buna-N seals are recommended for operating temperatures of -20°F (-25°C) to 200°F (95°C). Fluoroelastomer seals are available for higher temperature applications.

Pivot Pin/Pivot Bushing: Stainless Steel Series cylinders are shipped with plated steel pivot pins as standard. Sintered bronze pivot bushings are available as an alternative standard option. (5/16″, 1-3/4″, 2″ & 3″ bores supplied with pivot bushing only.)

Rod Seal: Precision machined rod seal groove provides a smooth sealing surface while positively retaining the seal without requiring additional components and relying on press fit containment.

Pre-lubricated: All cylinders are factory lubricated with a special high endurance oil mixture.

Pre-Tested: The quality of each cylinder is assured by testing each unit for leakage prior to shipment. Quality control provides added value to American cylinders.

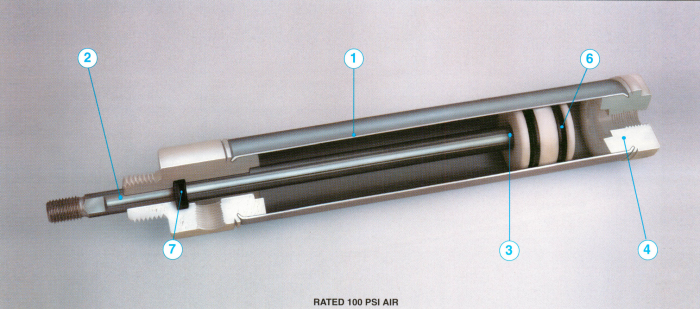

Aluminum 76-Series Pneumatic Cylinders

Hardcoated Aluminum Body Air Cylinders Available in 3/4″ thru 2-1/2″ Bore Sizes Feature Oversize Stainless Steel Rods, Dent Resistant Thick Walls and Heavy Duty Overall Construction.

Cylinder Body: Hard coated I.D. Aluminum Tubing has extreme hardness, excellent wear and seizure resistance, low coefficient of friction and high corrosion resistance. The aluminum body is twice as thick when compared to non-repairable stainless steel body cylinders.

Stainless Steel Rod: Ground & Polished Type 303 Stainless Steel rods are standard on the Aluminum 76 Series. All rods have wrench flats and stress relief grooves.

Piston Rod Assembly: Piston rods are threaded, anaerobically sealed, and machine staked into the piston for triple protection.

End Caps, Piston: High strength aluminum alloy.

Magnet for Sensing Switch Actuation: Optional, refer to American Cylinder’s MFC®span class=”auto-style7″> Series catalog for details.

Springs: Springs for spring action cylinders are made from music wire and designed for millions of cycles. Special spring forces are available.

Rod Guide Bushing: Standard on all models. The oil impregnated sintered bronze bushing increases the life of the cylinder rod and provides a non-abrasive bearing surface.

Buna-N U-Cup Rod & Piston Seals: U-Cup seals provide low breakaway friction and maximize cylinder life expectancy. Standard Buna-N seals are recommended for operating temperatures of -20° F (-25°C) to 200° F (95°C). Fluoroelastomer seals are available for higher temperature applications.

Pivot Bushing: Sintered bronze pivot bushings are standard on all universal mount models.

Rod Seal: Precision machined rod seal groove provides a smooth sealing surface while positively retaining the seal without requiring additional components and relying on press fit containment.

Prelubricated: All cylinders are factory lubricated with a special high endurance oil mixture.

Pre-Tested: The quality of each cylinder is assured by testing each unit for leakage prior to shipment. Quality control provides added value to American cylinders

Magnetic Field MFC-Series Cylinders

Both 76-Series and Stainless Steel Series Air Cylinders are Available with Internal Magnetic Piston Bands for Actuating Solid State Switches or Reed Switches. All Switches May be Purchased With or Without LED Indicating Lights. Available in Bore Sizes Ranging from 9/16″ thru 3″.

Cylinder Body Stainless Steel: Type 304 Stainless Steel manufactured to special mill specifications and tolerances to insure a long cylinder life.

Aluminum 76 Series: Thick wall hardcoated aluminum tubing exhibits excellent wear and seizure resistance while providing additional impact protection.

Stainless Steel Rod: Ground & Polished Type 303 Stainless Steel rods are standard on both the Stainless Steel Series and the Aluminum 76 Series. All rods have wrench flats and stress relief grooves (9/16″ bore excluded).

Piston Rod Assembly: Piston rods are threaded, anaerobically sealed, and machine staked into the piston for triple protection. Patent pending.

End Caps, Piston: High strength aluminum alloy.

Magnet for Sensing Switch Actuation: Internal magnet specially designed for use with American Reed or Hall Effect switches.

Springs: Springs for spring action cylinders are made from music wire and designed for millions of cycles. Special spring forces are available.

Rod Guide Bushing: Standard on all models. The oil impregnated sintered bronze bushing increases the life of the cylinder rod and provides a non-abrasive bearing surface.

Buna-N U-Cup Rod & Piston Seals: U-Cup seals provide low breakaway friction and maximize cylinder life expectancy. Standard Buna-N seals are recommended for operating temperatures of -20°F (-25°C) to 200°F (95°C). Fluoroelastomer seals are available for higher temperature applications.

Pivot Pin/Pivot Bushing: Stainless Steel Series cylinders are shipped with plated steel pivot pins as standard. (13/4″ & 2″ bores supplied with pivot bushing only.) Sintered bronze pivot bushings are available as an alternative standard option. Aluminum 76 Series models all utilize the oil impregnated sintered bronze bushing as standard.

Rod Seal: Precision machined rod seal groove provides a smooth sealing surface while positively retaining the seal without requiring additional components and relying on press fit containment.

Prelubricated: All cylinders are factory lubricated with a special high endurance oil mixture.

Pre-Tested: The quality of each cylinder is assured by testing each unit for leakage prior to shipment. Quality control provides added value to American cylinders.

Corrosion Resistant CR-Series Cylinders

Corrosion Resistant Stainless Steel Body Air Cylinders with Acetal Resin Heads, Stainless Steel Rods and Stainless Barrels Designed to Withstand a Variety of Harsh Environments. Available in Bore Sizes Ranging from 9/16″ thru 2-1/2″.

Stainless Steel Cylinder Body: Type 304 Stainless Steel manufactured to special mill specifications and tolerances to insure a long cylinder life.

Stainless Steel Rod: Ground & Polished Type 303 Stainless Steel rods are standard. All rods have wrench flats and stress relief grooves.

Piston Rod Assembly: Piston rods are threaded, anaerobically sealed, and machine staked into the piston for triple protection.

End Caps (Rod Guide & Rear Head): Made of Delrin* acetal resin developed by Dupont. A crystalline thermoplastic co-polymer made by the polymerization of formaldehyde.

Springs: Springs for spring action cylinders are made from stainless steel and designed for millions of cycles. Special spring forces are available.

Buna-N U-Cup Rod & Piston Seals: Pressure energized lip type seals provide low breakaway friction and maximize cylinder life expectancy. Standard Buna-N seals are recommended for operating temperatures of -20°F (-25°C) to 200°F (95°C). FDA approved seals are available as a standard Option (-35).

Rod Seal: Precision machined rod seal groove provides a smooth sealing surface while positively retaining the seal without requiring additional components and relying on press fit containment.

Prelubricated: All cylinders are factory lubricated with a special high endurance oil mixture. FDA approved lubrication is standard with the FDA seal Option (-35).

Pre-Tested: The quality of each cylinder is assured by testing each unit for leakage prior to shipment. Quality control provides added value to American cylinders.

We offer the above from the following Brands